The removal of all or specific man-made subsea structures from an O&G field is determined based on the most environmentally sustainable option for the area. With CEDAR® technology, materials such as concrete, metal, and plastic can be detected, localized, and differentiated.

Unlike traditional OAS and camera surveys, equipping your final ROV with a Tetrapulse or Octopulse sensor allows for the creation of an « electric image » of the seabed. This ensures clear evidence that the seabed has been restored to a pristine state, ready to support marine life and its natural habitat.

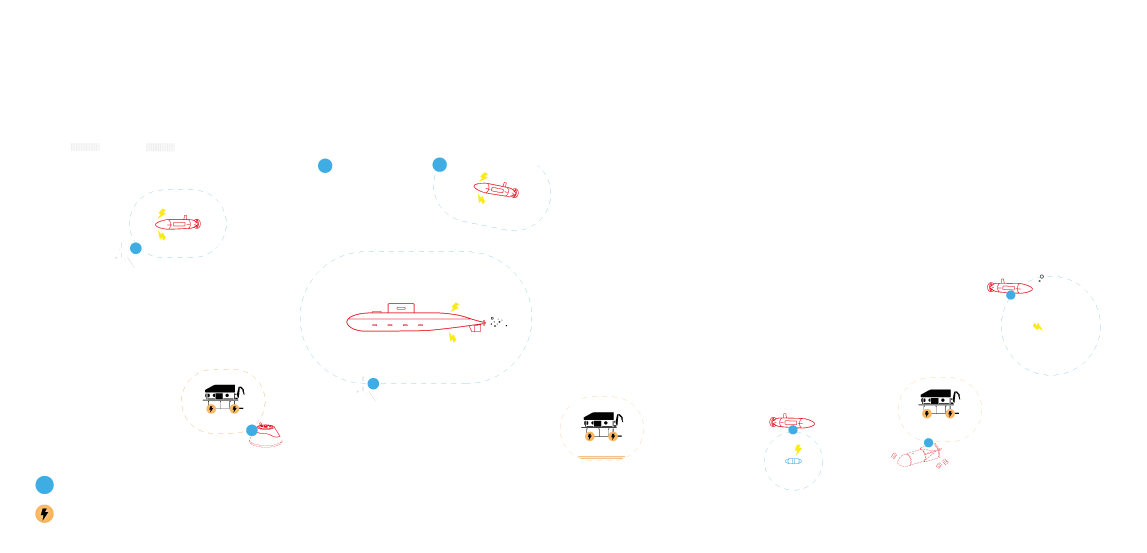

The Octopulse sensor, mounted on a ROTV, enables large-scale, high-speed initial studies. The Tetrapulse sensor, mounted on a mini-ROV, provides access to the most complex areas. CEDAR® technology delivers a high level of resolution, allowing differentiation between UXOs and debris, and ensures reliable detection of non-ferrous UXOs, outperforming magnetometers.

The inspection of buried cables and pipes is no longer limited to electromagnetic induction sensors, which are bulky and unsuitable for noisy, compact, or autonomous vehicles. The Tetrapulse and Octopulse sensors integrate seamlessly into AUVs or the skids of ROVs, preserving the maneuverability of the vehicles and their manipulators. Vessel time is optimized thanks to CEDAR® technology.

Stab cathodic protection inspections are very slow, making simultaneous mapping operations challenging and consuming significant vessel time. ESENSE sensors permits non-contact high accuracy measurements, even from fast-moving underwater vehicles such as AUVs or WROVs which emit significant electromagnetic noise.